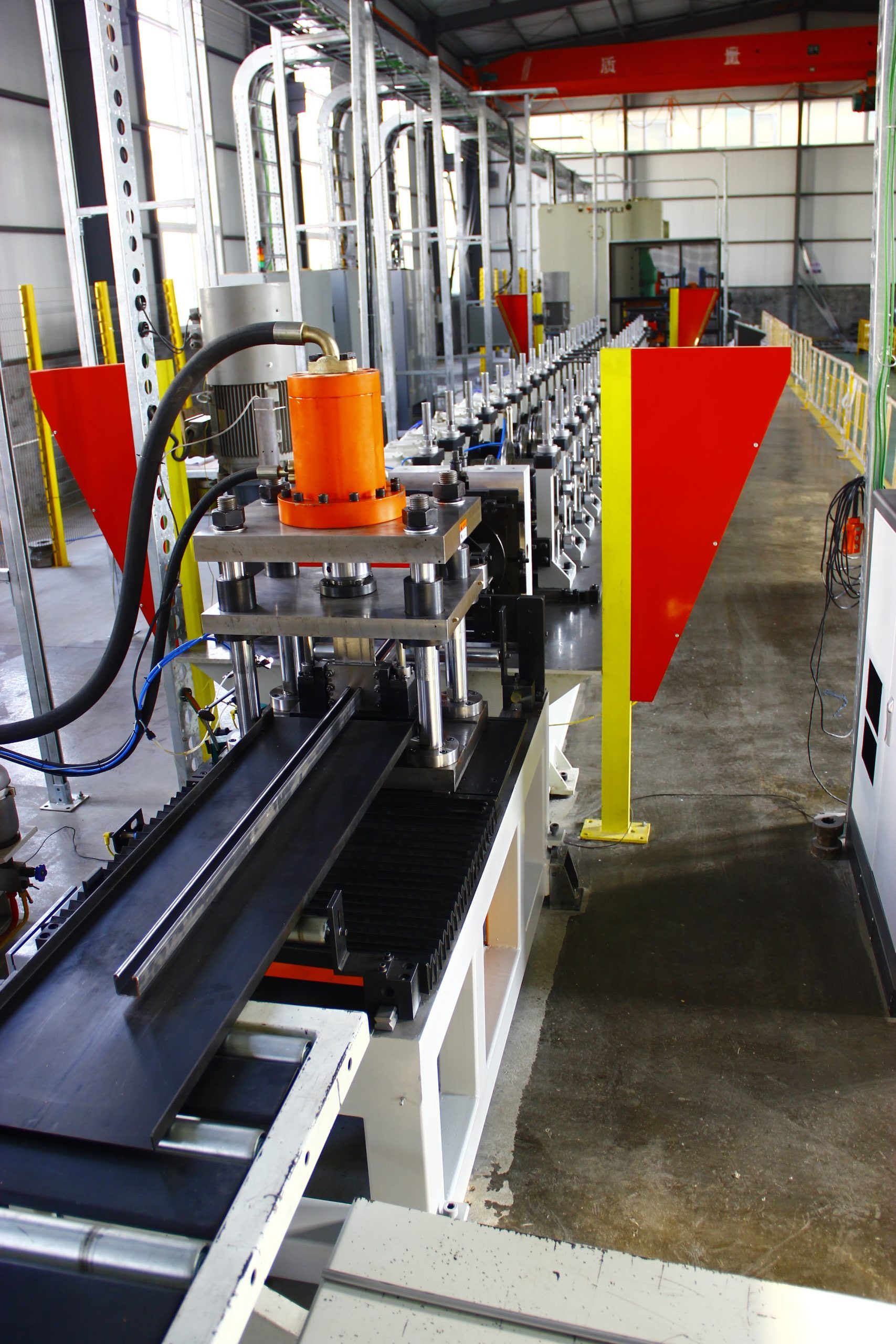

What is Roll Forming?

Roll Forming is a metal processing technique that involves bending and straightening operations to shape metal sheet into desired shapes and sizes. In the Roll Forming process, metal sheet passes through a series of rolling or bending wheels to undergo plastic deformation and ultimately achieve the desired product.

What materials are suitable for Roll Forming?

Roll Forming is mainly suitable for light to medium thickness metal sheet, such as low carbon steel, stainless steel, aluminum sheet, etc. The process parameters and equipment requirements for different materials.

What are the advantages of Roll Forming?

Roll Forming has the following advantages:

Continuous mass production for improved production efficiency;

Processing of complex shapes to meet different application needs;

High precision and quality control through adjustment of process parameters and equipment parameters;

Effective reduction in production costs and improvement in product competitiveness.

What are the application areas of Roll Forming?

Roll Forming is widely used in the construction, automotive, home appliance, electronics, furniture, sports equipment industries. For example, in the construction industry, it is used in door frames, guardrails, stair railings, etc.; in the automotive industry, it is used in door panels, roofs, chassis components, etc.; in the home appliance industry, it is used in refrigerators, washing machines, air conditioner housings, etc.; in the electronics industry, it is used in circuit boards, electronic component housings, etc.; in the furniture industry, it is used in chair legs, table legs, etc.; in the sports equipment industry, it is used in bicycle frames, ski boards, etc.

What are the basic steps of Roll Forming?

The basic steps of Roll Forming include metal sheet leveling, trimming, feeding, bending, straightening, and cooling. In each step, precise control of process parameters and equipment parameters is essential to ensure the quality and precision of the final product.

Why choose us? About