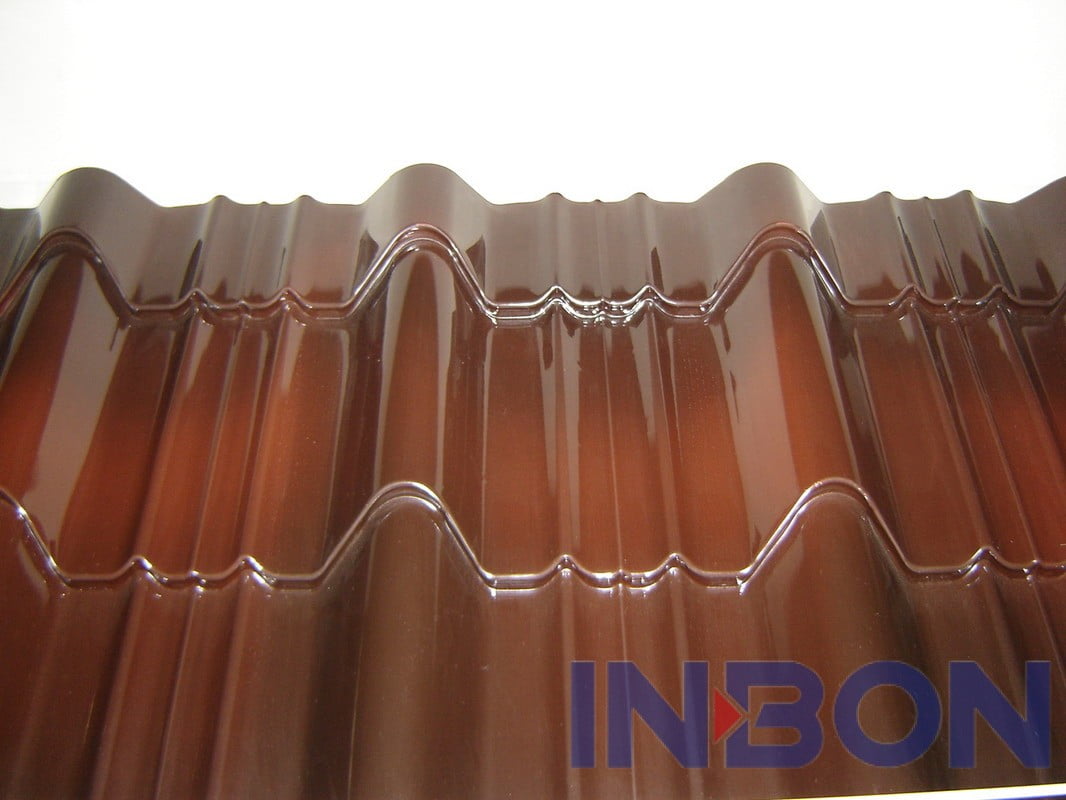

This roll forming machine is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling, then continuous rolling and cold-forming, automatically cut to the size and output the finished panel to the supporter. The equipment adopts PLC control, AC frequency and speed adjusting technology, and it realizes the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for steel structure.

- Main Technical Parameter

| No | Item | Parameter | Remark | ||

| 1 | Suitable

Material | Type | Color steel | ||

| Width(mm) | 925 | ||||

| Thickness(mm) | 0.35-0.6 | ||||

| Yield strength(Mpa) | 230-300 | ||||

| Coil capacity(T) | 5 | ||||

| 2 | Forming Speed(m/min) | About 4-5 | According to actual design | ||

| 3 | Roller Material | No.45 steel | with hard chrome painted. | ||

| 4 | Cutting Model | Hydraulic cutting | |||

| 5 | Power source | Type | 380V/3PH/50HZ | ||