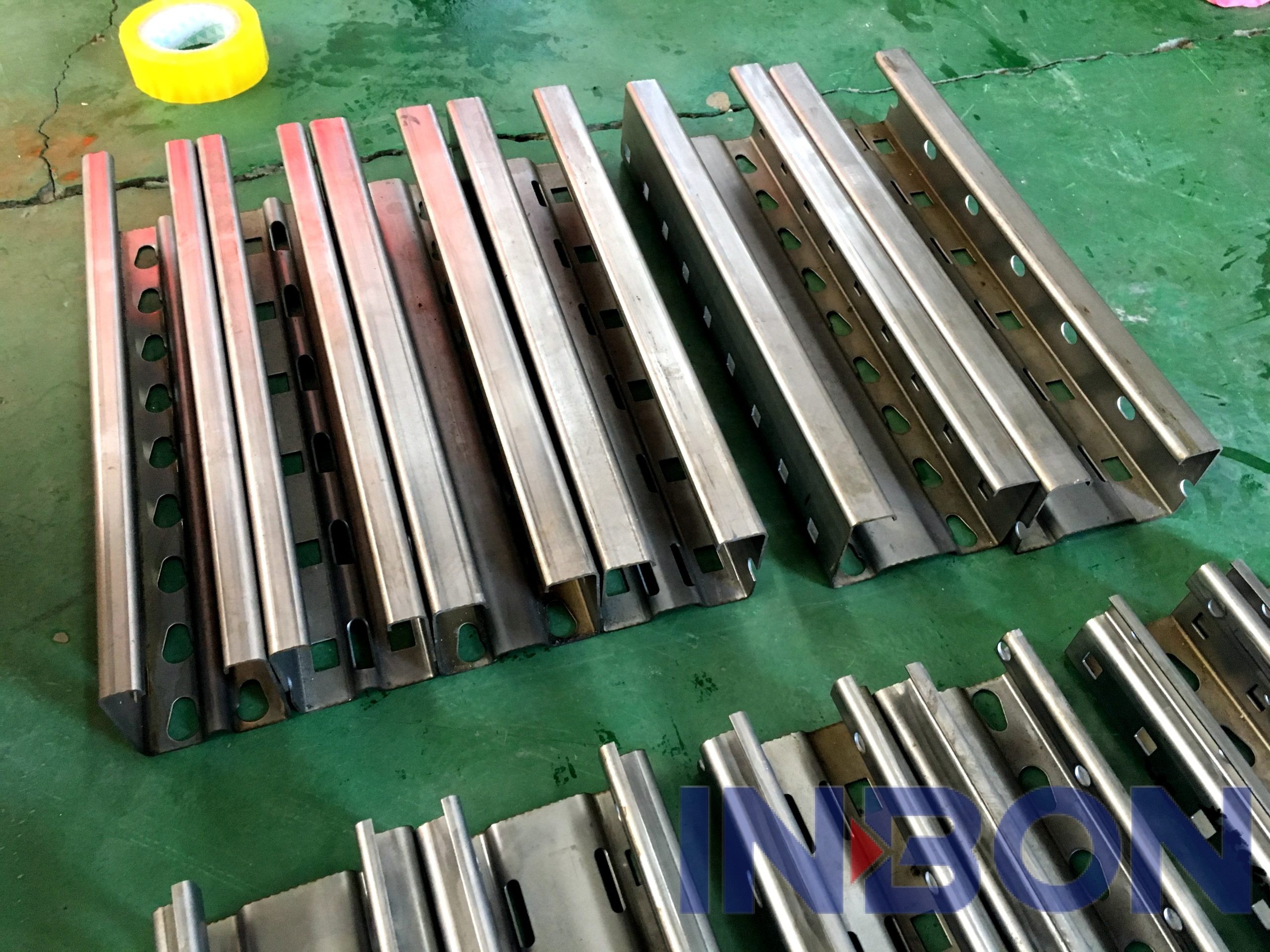

Custom roll forming machine for racking is a specialized machine used to manufacture rack components such as uprights, beams, and braces. It is designed to efficiently produce long lengths of metal profiles with consistent shapes and dimensions.

This Racking Upright Roll Forming Machine automatically adjusts to produce the Racking Upright according to client requirement. The machine is controlled by PLC, fully automatic working. It can automatically record the production quantity, automatically measure the length. It has Alarm Display and Emergency Stop function. All the machine working actions can be controlled by control panel.

The machine typically consists of a series of roll forming stations, where the metal strip or coil is gradually formed into the desired shape. The strip is fed through the machine, passing through multiple sets of rollers that gradually bend and shape it. Each set of rollers performs a specific forming operation, such as bending, punching, or notching.

The Custom roll forming machine for racking is capable of producing various types of rack profiles, including teardrop, double-slotted, or structural profiles. It can handle different gauges of metal, depending on the specific requirements of the racking system.

The machine is typically equipped with a control system that allows the operator to set the desired dimensions and specifications for the rack profiles. It also includes safety features to ensure the operator’s protection during operation.

Overall, a roll forming machine for racking is a crucial piece of equipment in the manufacturing process of racking systems. It enables efficient and precise production of rack components, ensuring high-quality and durable racks for various storage applications.