A steel coil blanking line is a manufacturing process that involves cutting large steel coils into smaller, flat pieces called blanks. The line typically consists of several machines and equipment that work together to perform various tasks, such as decoiling, leveling, and shearing.

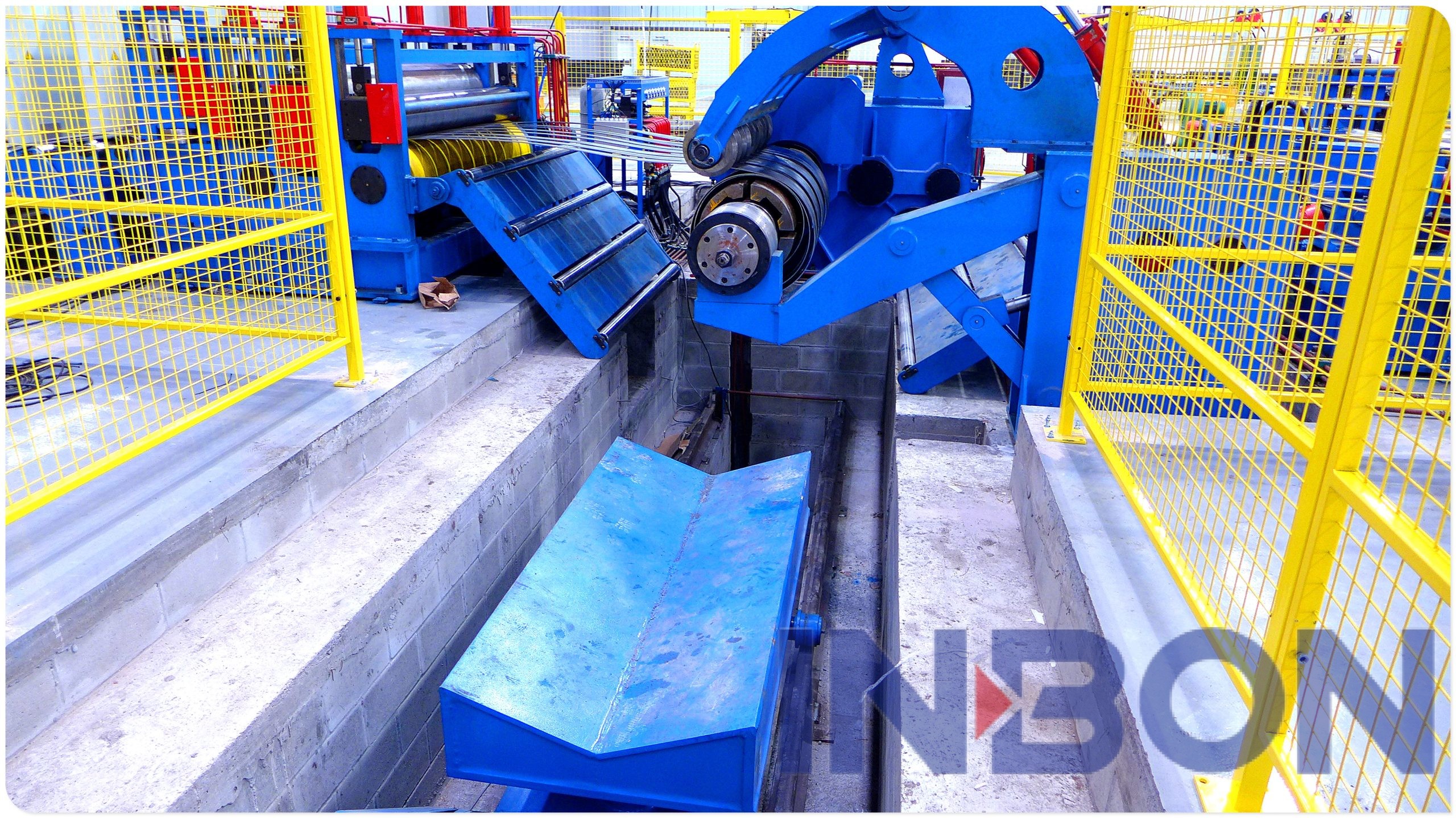

The process starts with a steel coil being unwound from a reel, known as decoiling. The coil is then fed through a leveling machine, which flattens and straightens the steel. This ensures that the blanks are of consistent thickness and flatness.

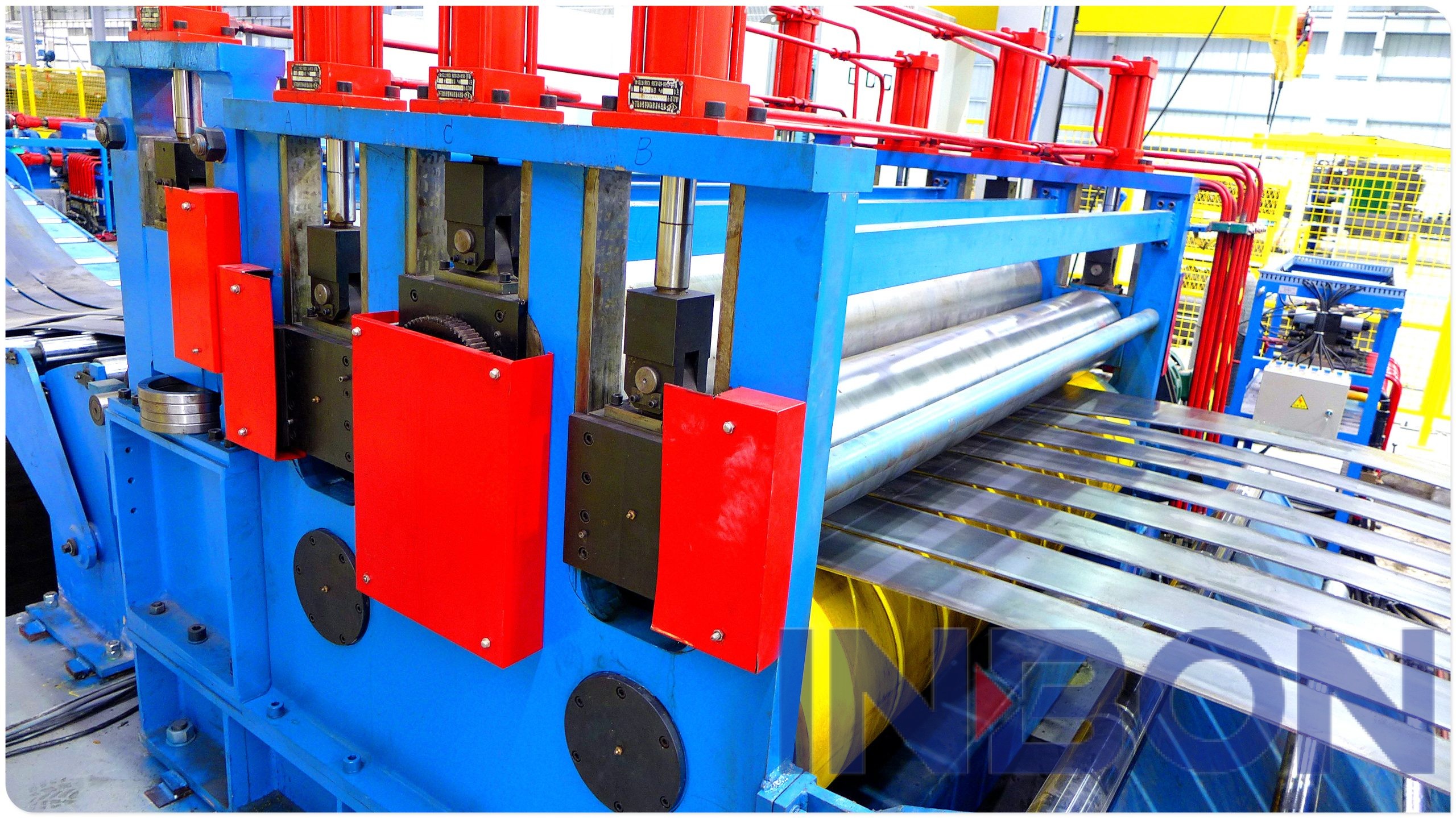

After leveling, the steel is fed into a shearing machine, where it is cut into individual blanks. The shearing machine uses sharp blades or dies to cut through the steel, producing precise and clean edges.

Once the blanks are cut, they are usually stacked or collected on a conveyor belt for further processing or packaging. Some blanking lines may also include additional equipment, such as edge trimming machines or stacking systems, to further enhance the efficiency and precision of the process.

Steel coil blanking lines are commonly used in industries that require flat steel blanks for various applications, such as automotive, appliance manufacturing, construction, and metal fabrication. The line allows manufacturers to efficiently and accurately produce large quantities of blanks from steel coils, reducing waste and improving productivity.