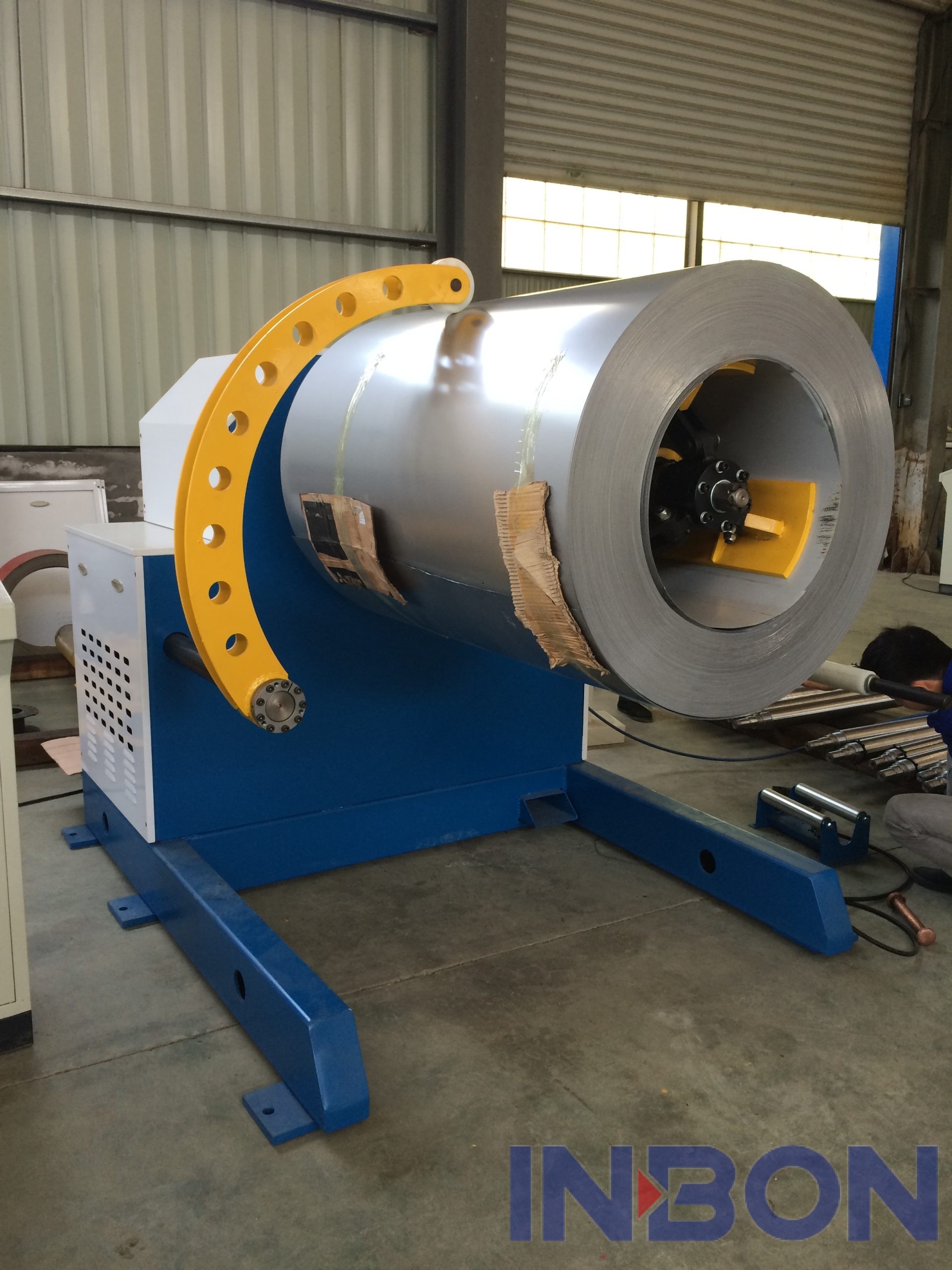

The uncoiler for roll forming machine is a key component of the roll forming machine, which is used to unwind the coil of steel sheet and supply it to the forming mechanism. The uncoiler plays a crucial role in ensuring the smooth operation of the roll forming process. It must be able to maintain a constant tension on the steel sheet during unwinding to ensure that the sheet does not sag or vibrate, which could lead to defects in the formed products.

In addition to maintaining constant tension, the uncoiler also needs to be able to adjust the speed of unwinding according to the requirements of the forming process. During the forming process, different parts may require different forming speeds, and the uncoiler must be able to adjust its unwinding speed accordingly to ensure that the sheet can be supplied to the forming mechanism at the desired speed.

Moreover, the uncoiler must have a robust structure and be able to withstand the continuous operation of the roll forming machine. It must also be easy to maintain and repair, as it is a crucial component of the roll forming machine and needs to be kept in good working order to ensure the stability and efficiency of the roll forming process.

In summary, the uncoiler for roll forming machine is a crucial component that ensures the smooth operation of the roll forming process. It must maintain constant tension on the steel sheet, adjust its unwinding speed according to the requirements of the forming process, and have a robust structure that can withstand continuous operation.

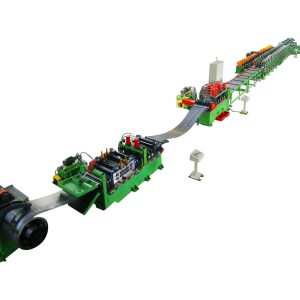

Related products

Automotive parts roll forming machine

Roll Forming MachinesGuardrail roll forming machine cassette type

Roll Forming MachinesAngle roll forming machine

Roll Forming MachinesStep tile forming machine

Roll Forming Machines