Stainless steel coil cut to length line is a machine used in the steel industry to cut steel coils into specific lengths. The line consists of several components, including a decoiler, straightening unit, feeder, shearing machine, and stacker.

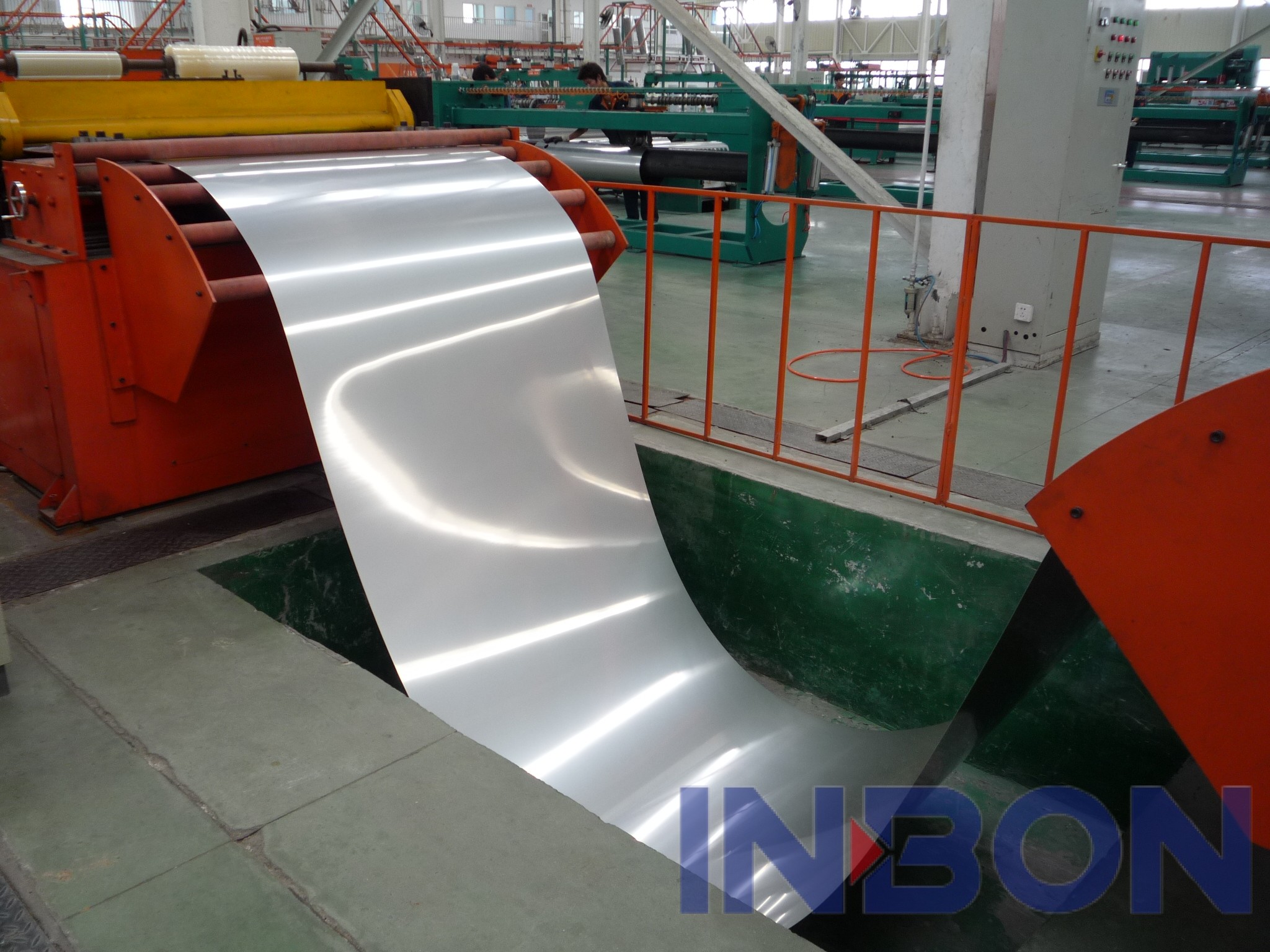

The process begins with a steel coil being loaded onto the decoiler, which unwinds the coil and feeds it into the straightening unit. The straightening unit consists of a set of rollers that remove any coil set or curvature in the steel, ensuring a flat and straight surface.

Once the steel is straightened, it is fed into the feeder, which accurately measures the length of steel required for each cut. The feeder then advances the steel to the shearing machine, which cuts the steel to the desired length. The shearing machine can be equipped with different types of blades, such as rotary or flying shear, depending on the specific requirements.

After the steel is cut, it is transported to the stacker, which neatly stacks the cut pieces for easy handling and transportation. The stacker can automatically adjust the height and width of the stack, depending on the length and quantity of the cut pieces.

Overall, a steel coil cut to length line is a highly efficient and precise machine used in the steel industry to produce steel sheets or strips of specific lengths, ready for further processing or direct use in various applications.